Build Experience with Printed Parts

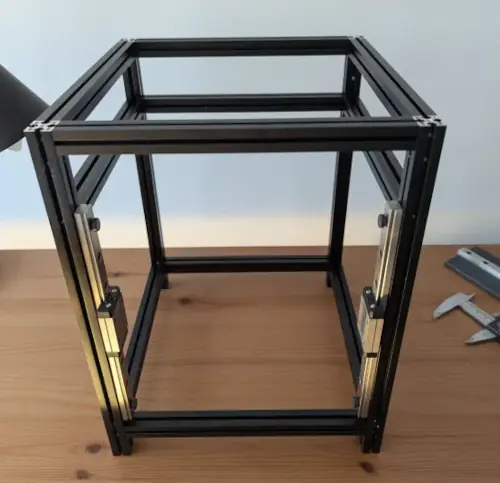

The best way to avoid issues and improve the experience is with several test fits with printed parts and iteration until the desired outcome. Sometimes, it's impossible to predict the ergonomic challenges of a build just by the CAD. This is especially true for a printer based on the widely hated 1515 extrusions.

Building the frame itself is super simple compared to what I'm used to on bigger printers. Once I had my blind-joint holes drilled I probably got it done in less than an hour.

The tricky part is always with the nut situation, so zruncho suggested reworking the plates to have all holes line up with a 15mm spacing, which is perfect for no-drop nuts. That way we won't have to worry about this issue ever.

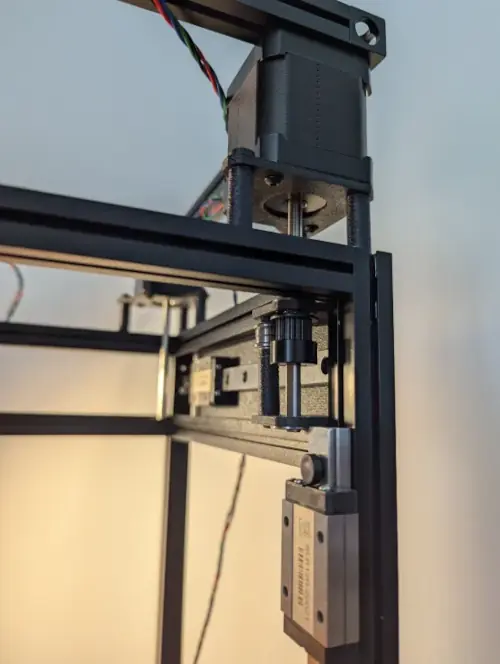

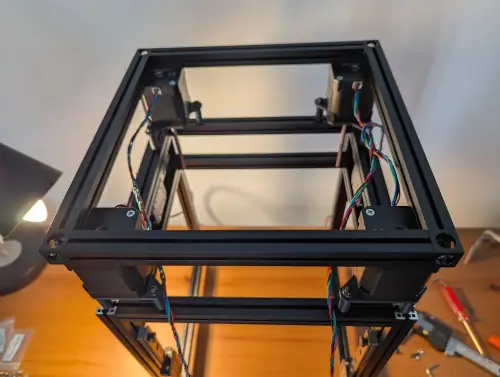

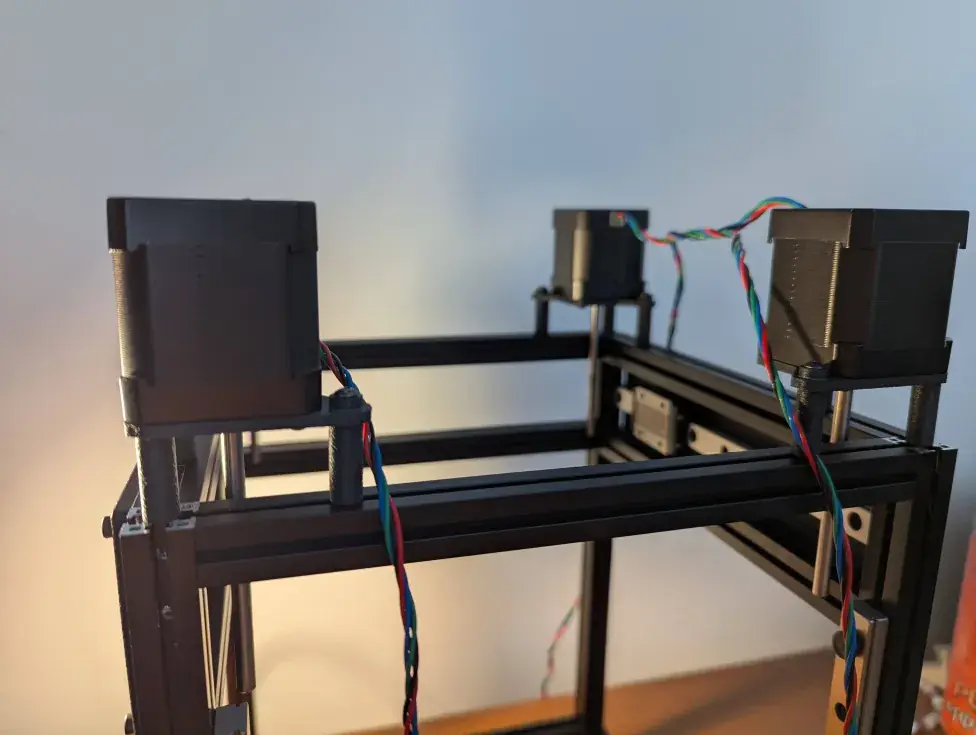

Building the XY gantry is relatively straightforward, however, to make the alignment as easy as possible we need to reconsider what surfaces to use for indexing. The stepper mount assembly is already on point and the tophat brace ties everything together nicely.

I'm hoping to cut my X-rail to length on the weekend, so the next update should be with a belted-up gantry. Among other things, we need to work out the ideal CPAP tube mounting positions to finalize the sheet metal parts.