Monolith Gantry Updates

These posts are sourced directly from the Monolith Discord #updates channel. For questions or real-time updates, join the dedicated Monolith Discord server.

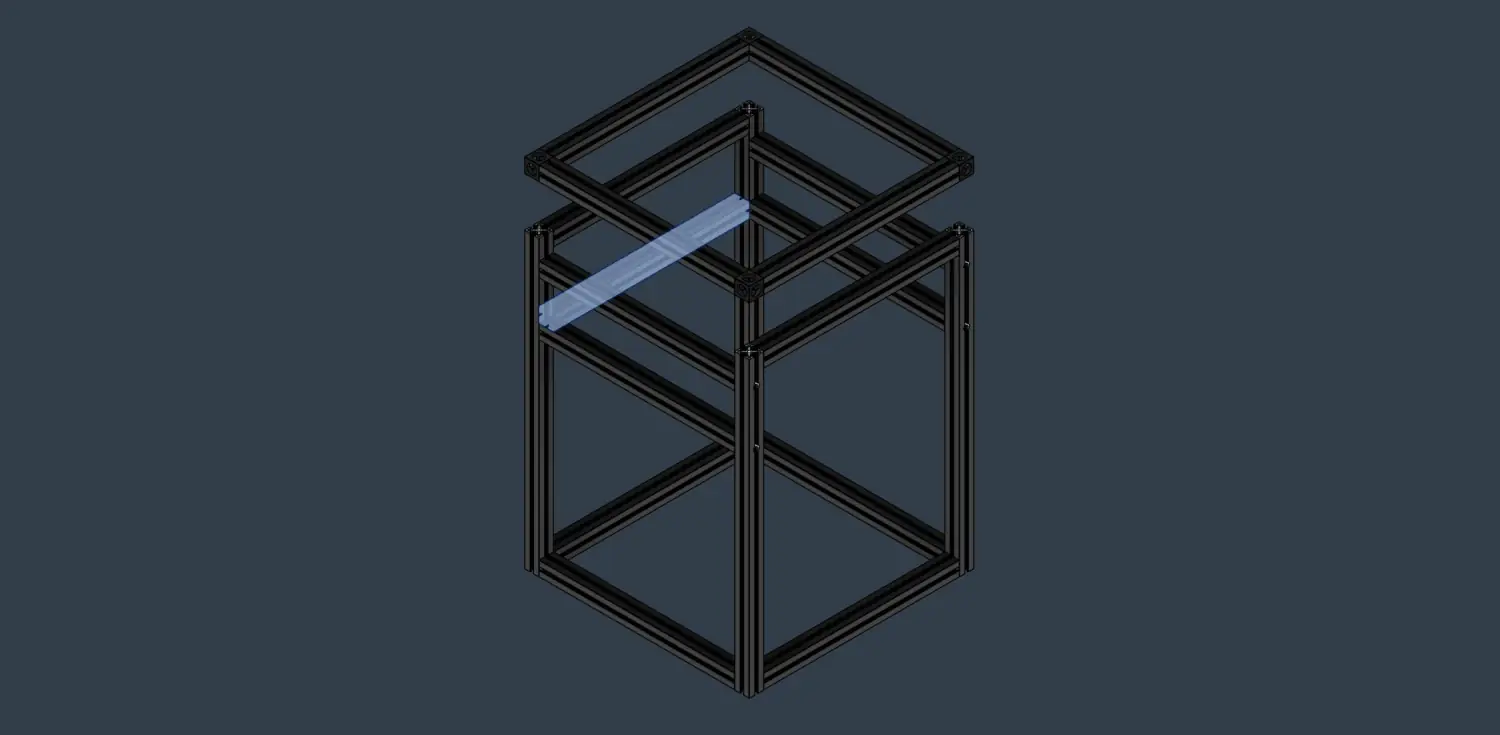

Fixed Gantry Conversion 6 - Kinematic Z

This is likely my final post about the conversion itself. Apart from some wiring and modifying the Klipper configuration, this is almost a fully functional printer again, ready for Z-motion prototyping…

··CloakedWayne·#Monolith Kinematic-Z

·

Fixed Gantry Conversion 6 - Kinematic Z

Melting Performance Improvements

We have shown a significant temperature drop in the melt zone with the sims. To counter this, I designed a 360 in the middle to achieve a more consistent viscosity across the cross section at the nozzle. Despite our current sub-optimal HF geometry, the print quality doesn’t seem to be affected noticeably compared to the SF design, which definitely has worse melting performance…

··CloakedWayne·#Monolith Toolhead

·

Melting Performance Improvements

Separate Shield - Toolhead Development

We'll make the bottom of the main body completely flat flush with the Beacon mounting surface. This will improve printability and lessen the potential warping.

··CloakedWayne·#Monolith Toolhead

·

Separate Shield - Toolhead Development

Beacon Clearance - Toolhead Development

It appears that with the relocated thermistor, we can reduce the Beacon Y-offset from 18mm to 15mm, which means that rear lead screw clearance is possible,...

··CloakedWayne·#Monolith Toolhead

·

Beacon Clearance - Toolhead Development

Updated Roadmap - Toolhead Development

Now that all of the M0 prototype content is out, and there still aren’t many interesting things I could share about the ongoing toolhead development, I thought I’d summarize what to expect in this next phase:…

··CloakedWayne·#Monolith Toolhead

·

Updated Roadmap - Toolhead Development

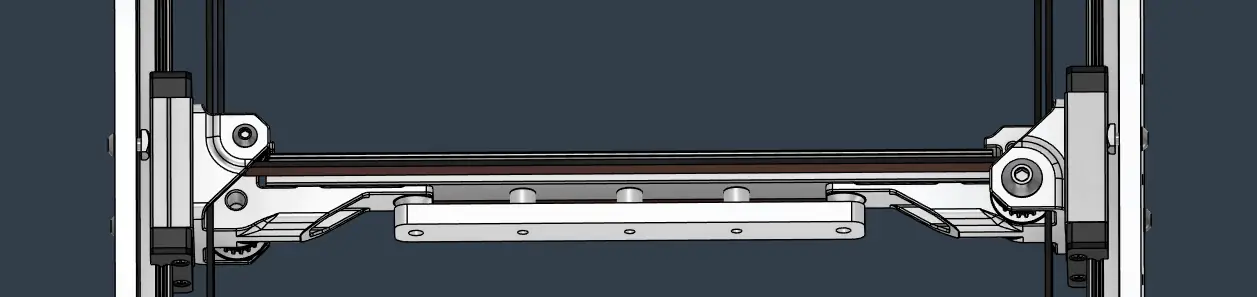

IS revisit with an Improvised Backer

We already discussed the unsupported MGN12H X-rail on the M0 and how the frequency drop was slightly more pronounced in the middle than I’m used to with my 300mm and Carbonara. Fortunately, I had a spare 5mm-thick bed mounting plate that I could cut and drill to make a simple backer for the middle of the rail. Three holes are directly from the rail, and the additional two also sandwich the XY joints…

··CloakedWayne·#Monolith Zero #Input Shaper

·

IS revisit with an Improvised Backer

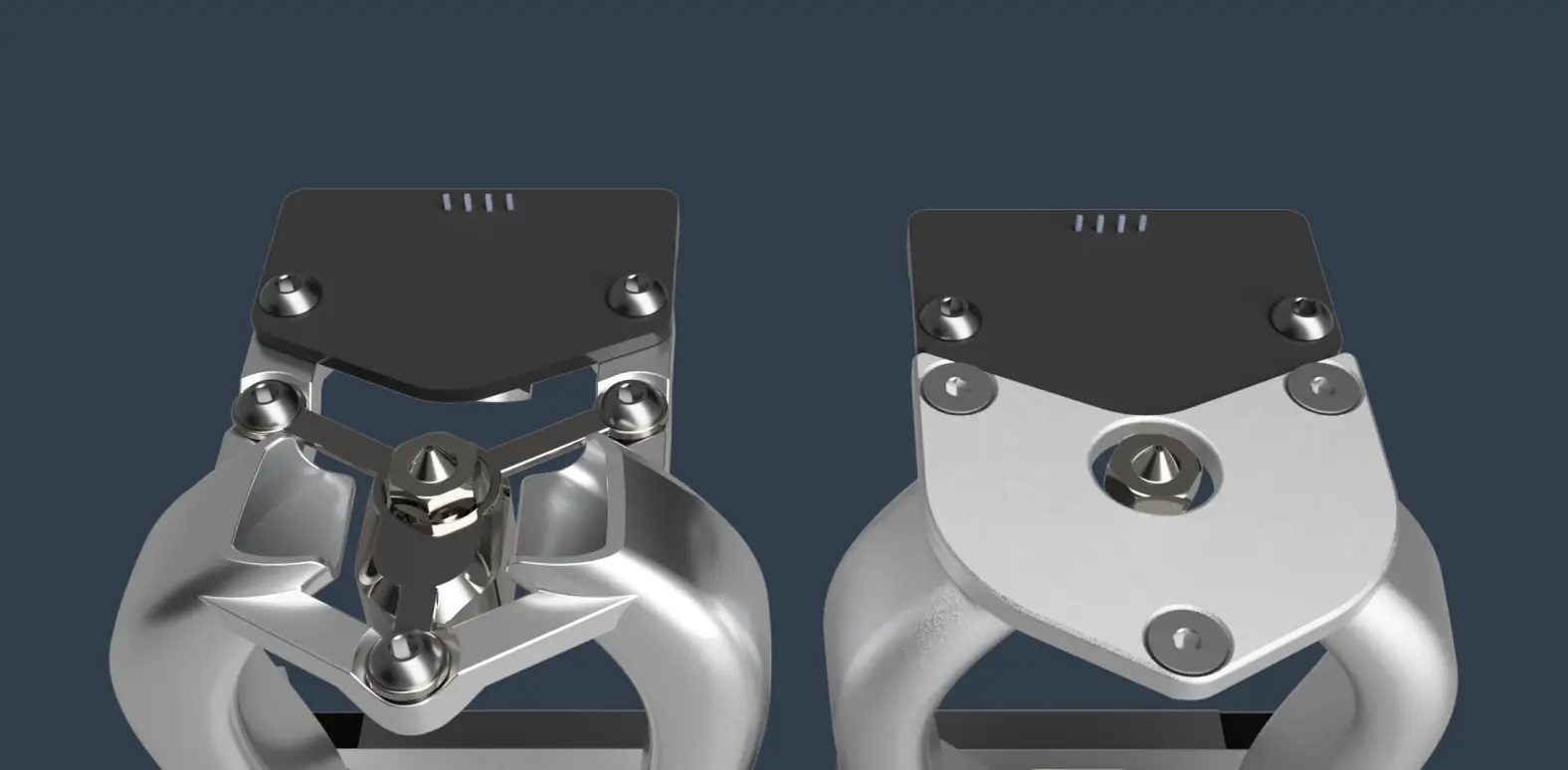

Extruder Improvements - Toolhead

Here’s what I’ve been working on for the non-kit extruder:…

··CloakedWayne·#Monolith Toolhead

·

Extruder Improvements - Toolhead

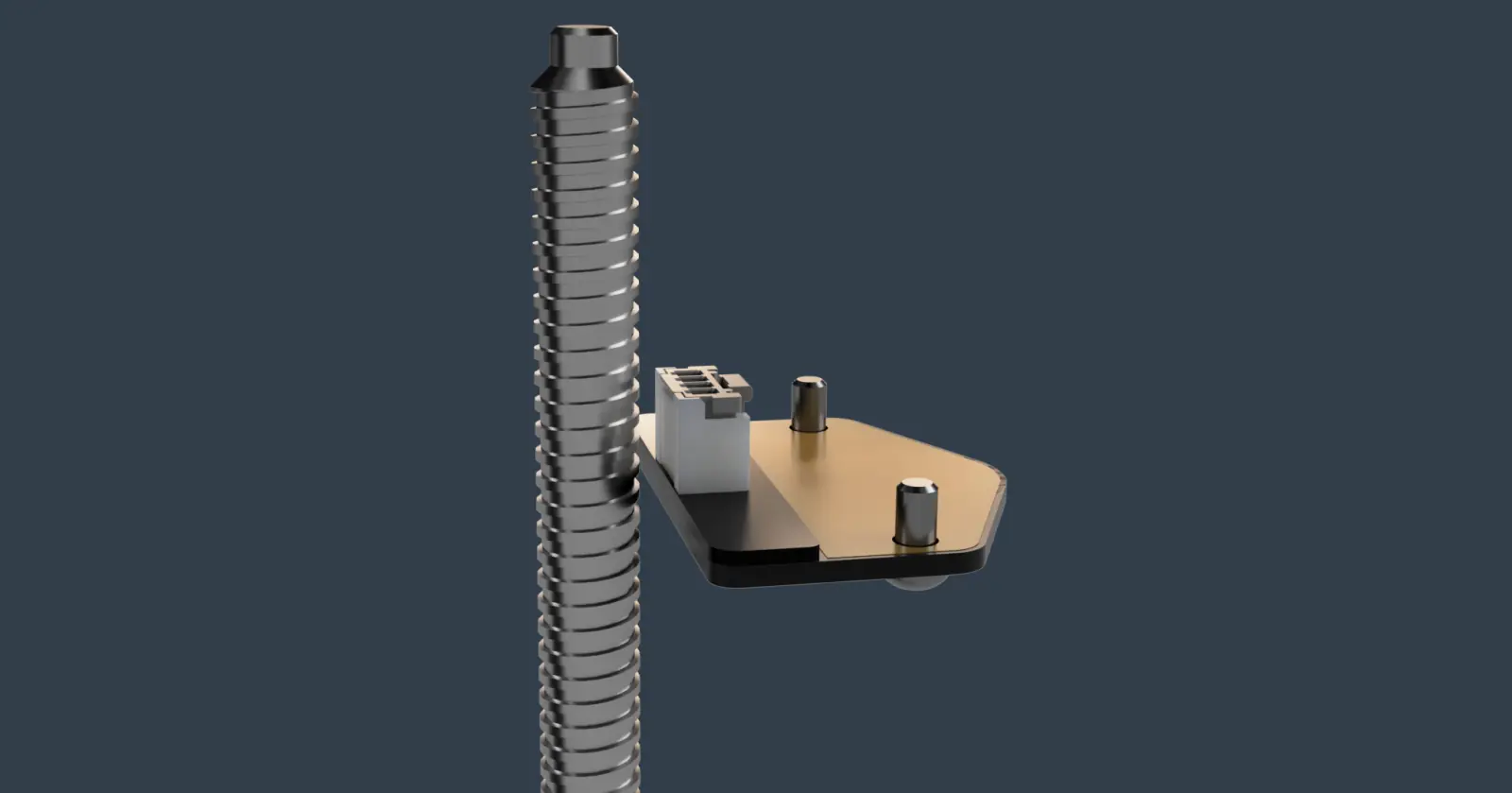

Revisiting the Milled Copper Block

I’ve never actually seen the full potential of my old milled heat block. Back then, we had a limitation with the filament grip. Fortunately, the first toolhead design provides a great platform for testing different hotend blocks and extruder internals…

··CloakedWayne·#Monolith Toolhead

·

Revisiting the Milled Copper Block

Input Shaper Graphs 3 - Monolith Zero

We haven’t observed a significant increase in frequency with the all-metal gantry compared to the enhanced FDM one, which makes sense since the moving mass is probably heavier, offsetting the rigidity increase…

··CloakedWayne·#Monolith Zero #Input Shaper

·

Input Shaper Graphs 3 - Monolith Zero

Insulation Planning - Monolith Zero

The heat loss through the aluminum panels is significant. Without the sheet cooling (acting as bed fans) and the extra heat from the bed, steppers, hotend, and CPAP, the temperature can barely reach about 50°C in 30 minutes…

··CloakedWayne·#Monolith Zero

·

Insulation Planning - Monolith Zero