Design Considerations for Maintenance

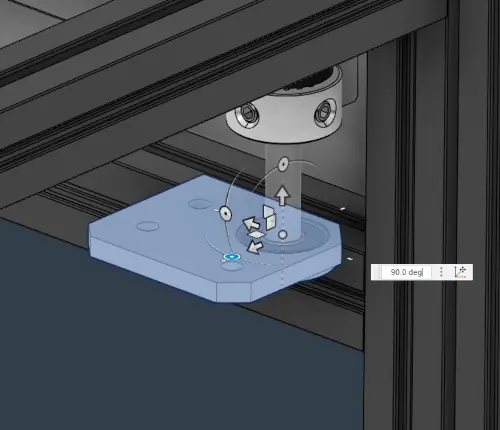

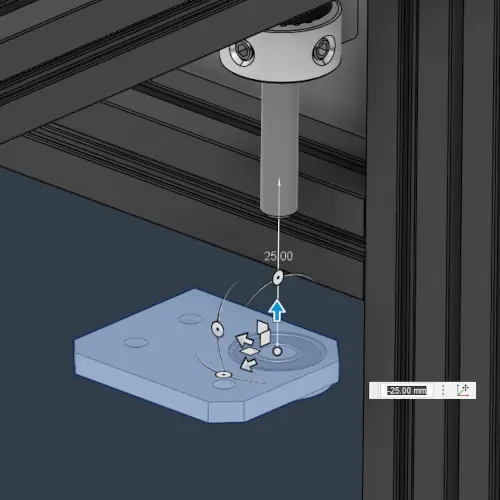

The XY gantry serviceability is very important on small machines, as it's quite difficult to work inside the printer. The 1515s and the hard-to-remove panels further add to this issue. It's a priority to make the gantry bearings and idlers easily replaceable, so I looked at what could be done.

I discovered that the front plates are quite accessible through the Y-rail mounting plate's cutout and the part can be rotated and then pulled off the shaft. The rear mounting plates also have 2 screws, one for the Y extrusion, and one for the rear extrusion. By the looks of it, there are no downsides to doing the same as the front one, with 2 screws for the Y extrusion.

.webp)

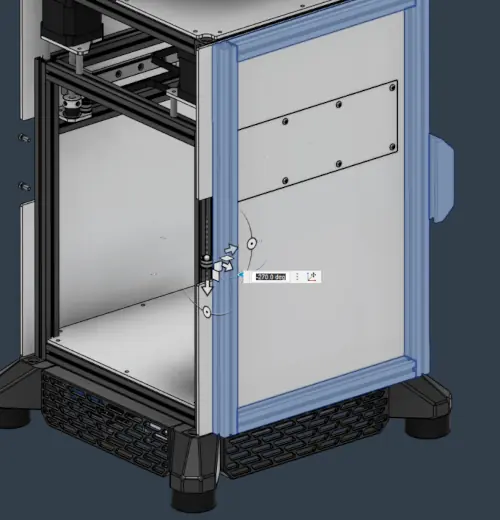

Another thing that's very important to me is the 270-degree door. I've spent nearly a day working on the hinge location to keep the seamless integration of the door.

It's not quite there yet, but it's been very refreshing to work on a single CAD with unsolved problems for days. Also, I've been experimenting with skirt patterns, there's a newer render below. It'll probably be a good idea to share blank templates as well.

This is pretty much what I'll be working on until either the toolhead or the LDO milled kit arrives.