Different HF Melt Zone Geometries

As discussed before having these cheap AF hotend blocks and the new design without the MZA allows us to experiment with HF geometries.

Currently, I'm using the flat melt zone in the middle which is just a 1.2x4mm slot cross-section. Even though I haven't made any apple-to-apple comparisons, I don't recall being able to do 80mm3/s with so little die swell on a 500mm long extrusion length with the CNC copper block.

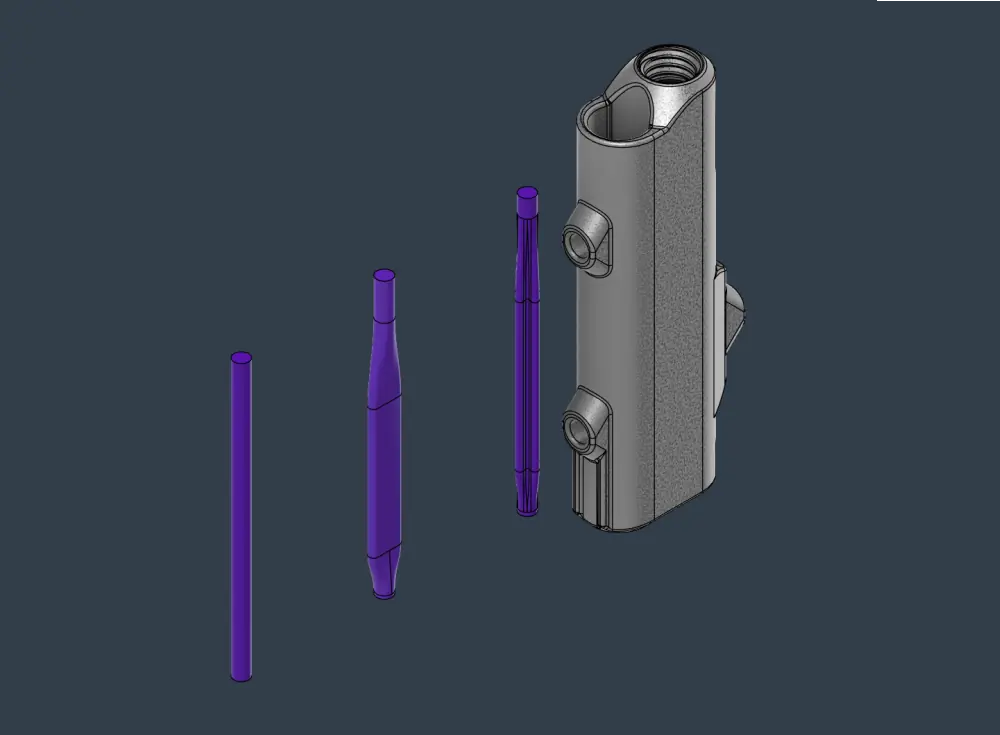

By moving the thermistor closer to the melt zone I wanted to choose a HF geometry that takes up less space in Y. The result is a 4 leaf clover style cross-section similar to Bozzle's.

With steel keeping the melt zone temp delta in check is very geometry-dependent. Adeo has already run some sims and has a pretty good idea of where to go from here in the future.

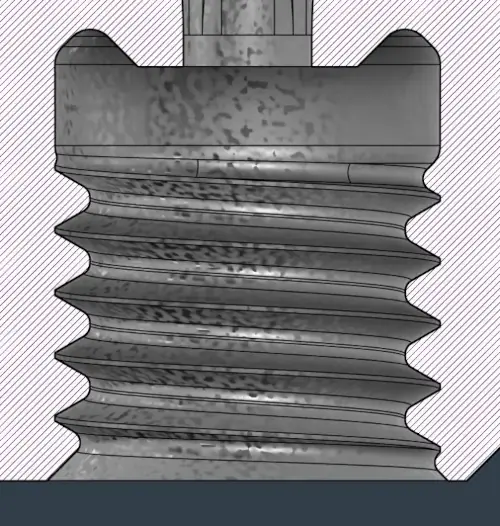

The built-in lips meant to work around the washers are already in place for the next order. The thread relief is 2mm + 45deg chamfer which has been workable even without grinding down the end of the M6 tap. Maximizing the heat transfer between the nozzle and the block is vital, so I'd like to keep as much thread engagement as possible.