DoF Concept - Kinematic Z Development

The main problem with RatRig-style, bed carrier-less kinematic designs is that the pivot point is very far from the Z-rail, which means very low stiffness in XY for the bed. No wonder they're using MGN15 or similar to get as much torsional stiffness without a load as possible.

In the last Z motion post I mentioned that I want to maximize rigidity without oversizing Z rails and arms by preloading everything in XY.

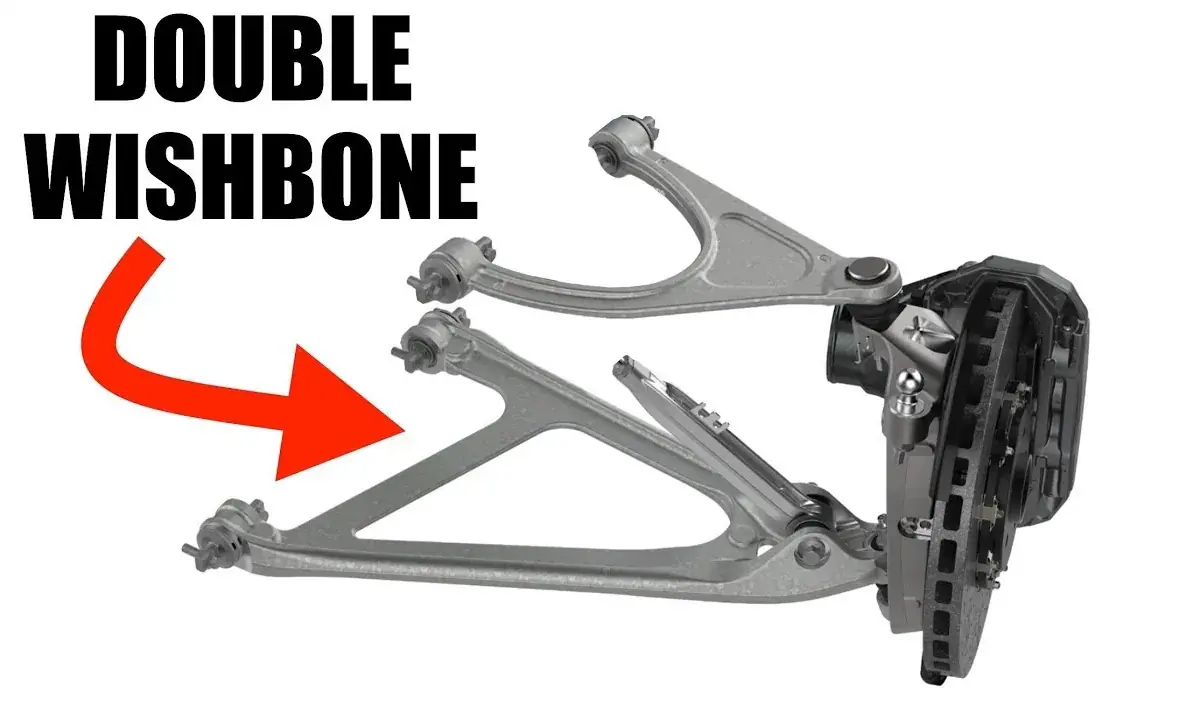

The inspiration comes from the automotive industry, double-wishbone suspensions to be more exact.

The idea is to "hang" the bed on 3 wishbones that sit at a certain vertical angle to get the desired XY preload from gravity. The GE5Cs would be as close to the Z rails as possible and the cylindrical joints would be very close to the bed's edge. This is a 2+2+2 setup without using point contacts or sliding joints. The triangles and the close-to-straight load paths would mean good material efficiency, which is important for SLM designs.

My goal is to make this thing happen with only 2 or 3 SLM parts per corner.

The video below is only the DoF concept and isn't meant to show what the parts and the layout would look like!