FirstTry™ as always - My Toolhead Evolution

This post is about my front rail toolhead journey. It showcases how this particular CAD has evolved over the past year based on what I learned from the community and my mistakes, leading up to the design we're currently developing here. It's not meant to take away anything from other toolhead developers' work, who have made significant advancements in this area that we can all build on.

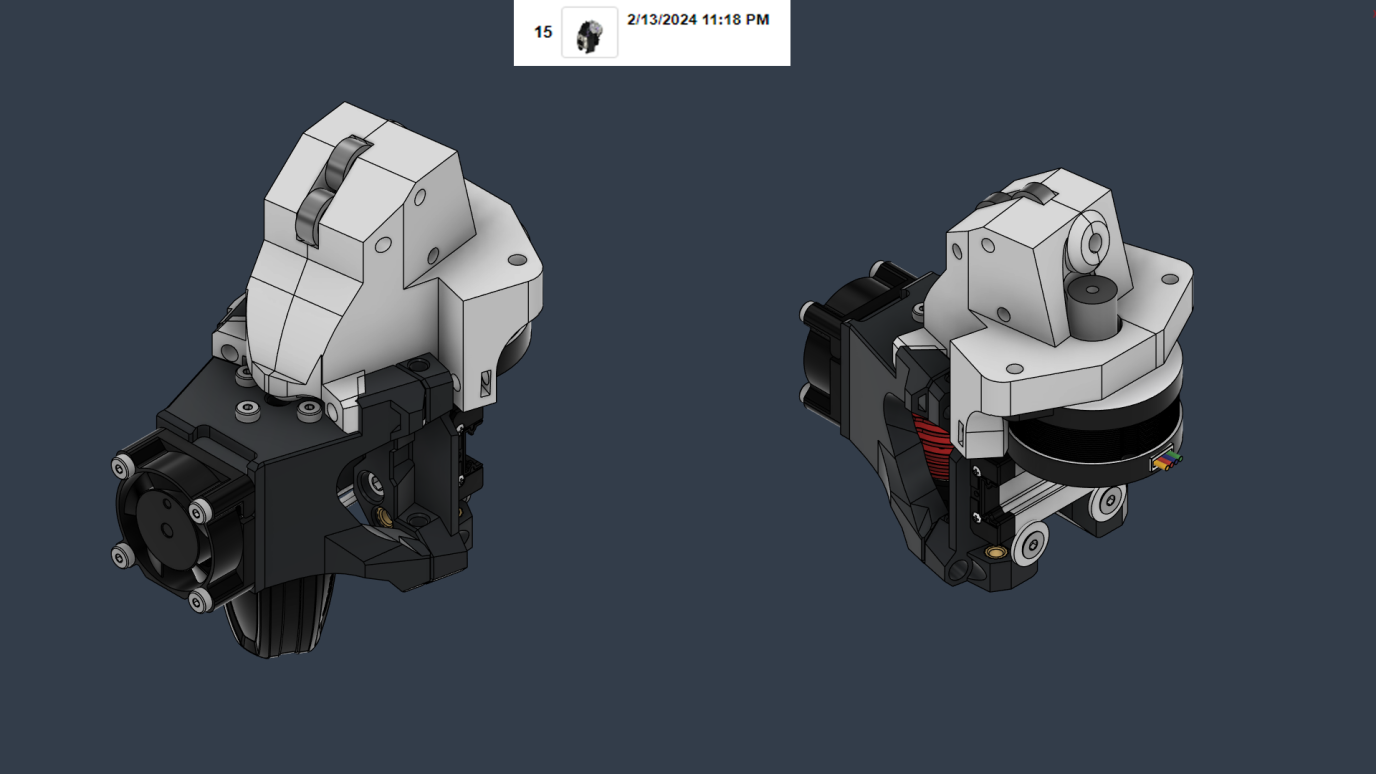

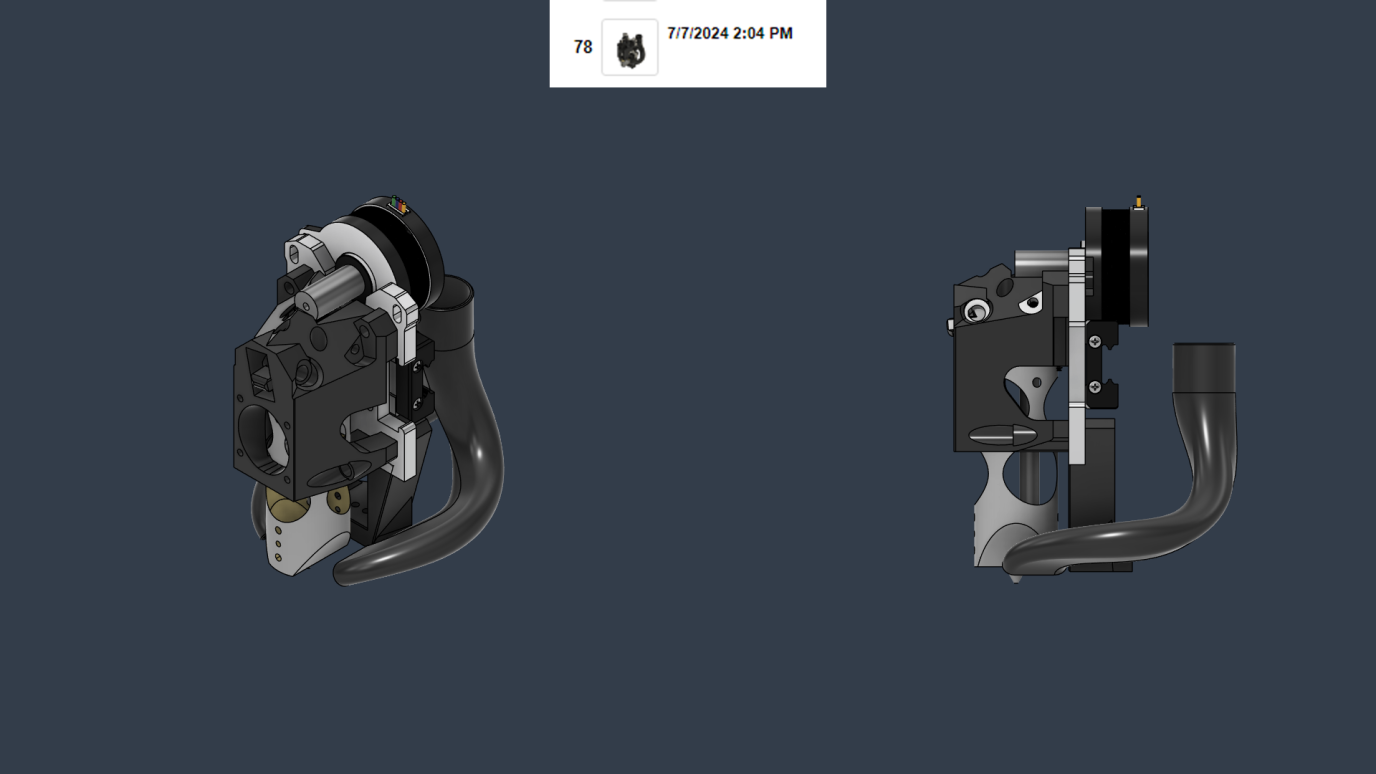

The first stage was when I learned we had to have the COM vertically between the 2 ball races to avoid the most significant performance losses. At that time for me, this meant designing a low COM extruder for Archetype

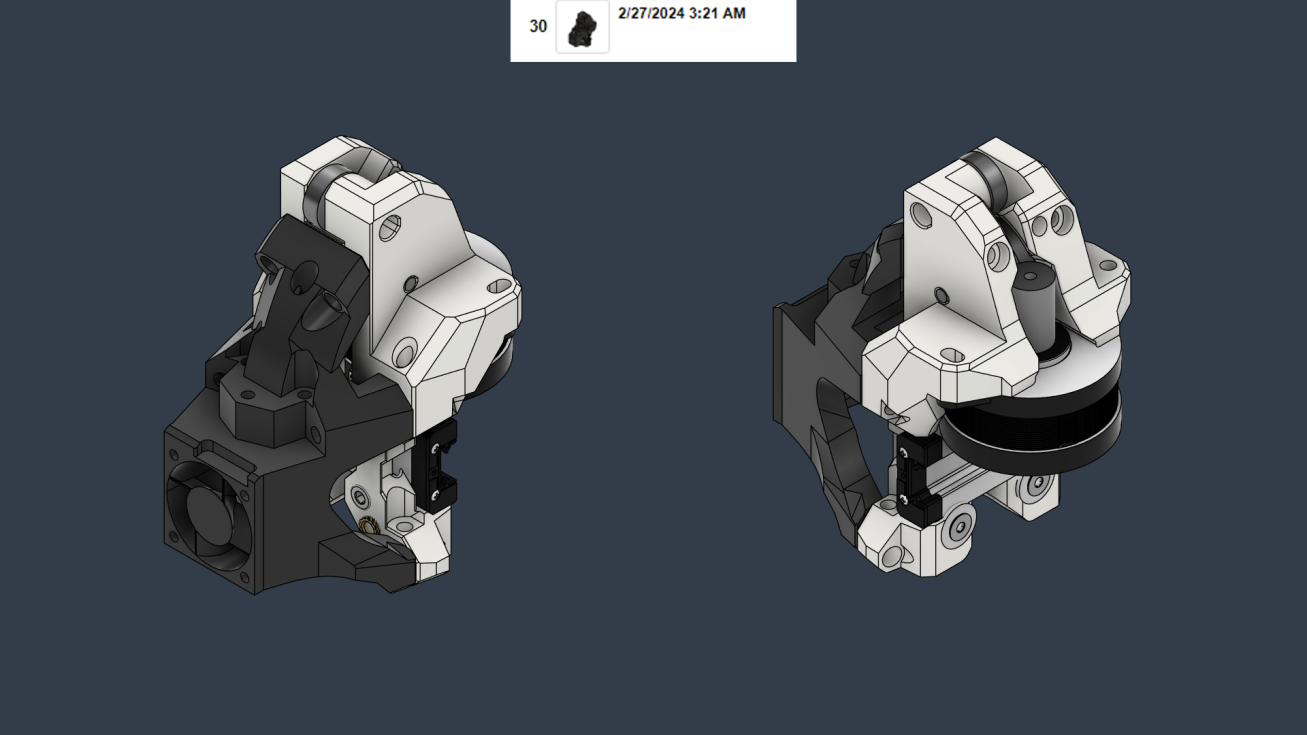

A more elegant solution came to life when I reduced the part count and integrated the extruder into the carriage mount making it the last fully printed design I used on my printer. This was also when Adeo started getting rid of parts and some of the modularity with his F-toolhead design.

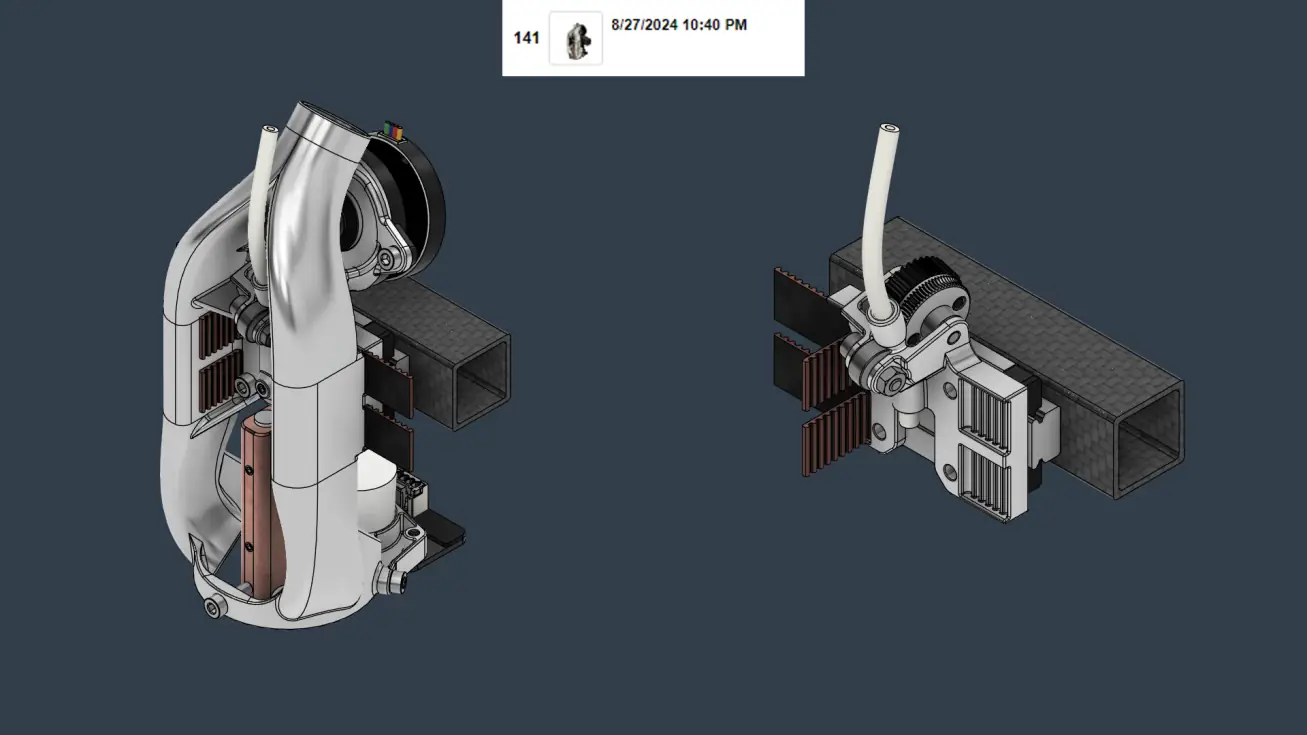

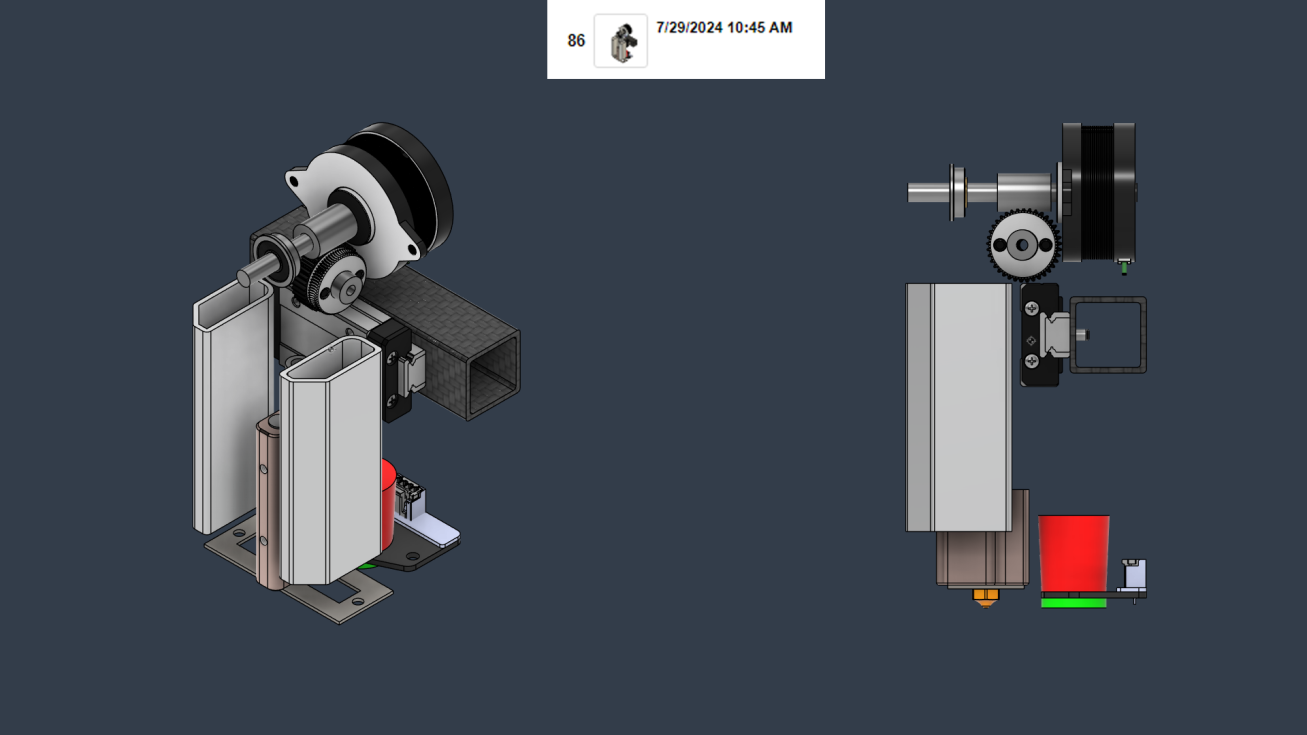

Around the time when I was developing the sheet metal gantry, I thought it would be pretty cool to handle the belt and extruder mounting with a simple sheet metal carriage that would serve as the base for more rigid hotend mounting with still some modularity left. This design still used the modified Breakneck ducts.

After running the previous setup for a few months I grew tired of its flaws. The duct made accessing the extruder parts very difficult and with a brass worm and a hardened steel worm-gear I was having wear issues. The double MZE BS that I had didn't help, either. I wanted to switch to Chube with a rear duct (by Adeo) and replace the worm with a steel one.

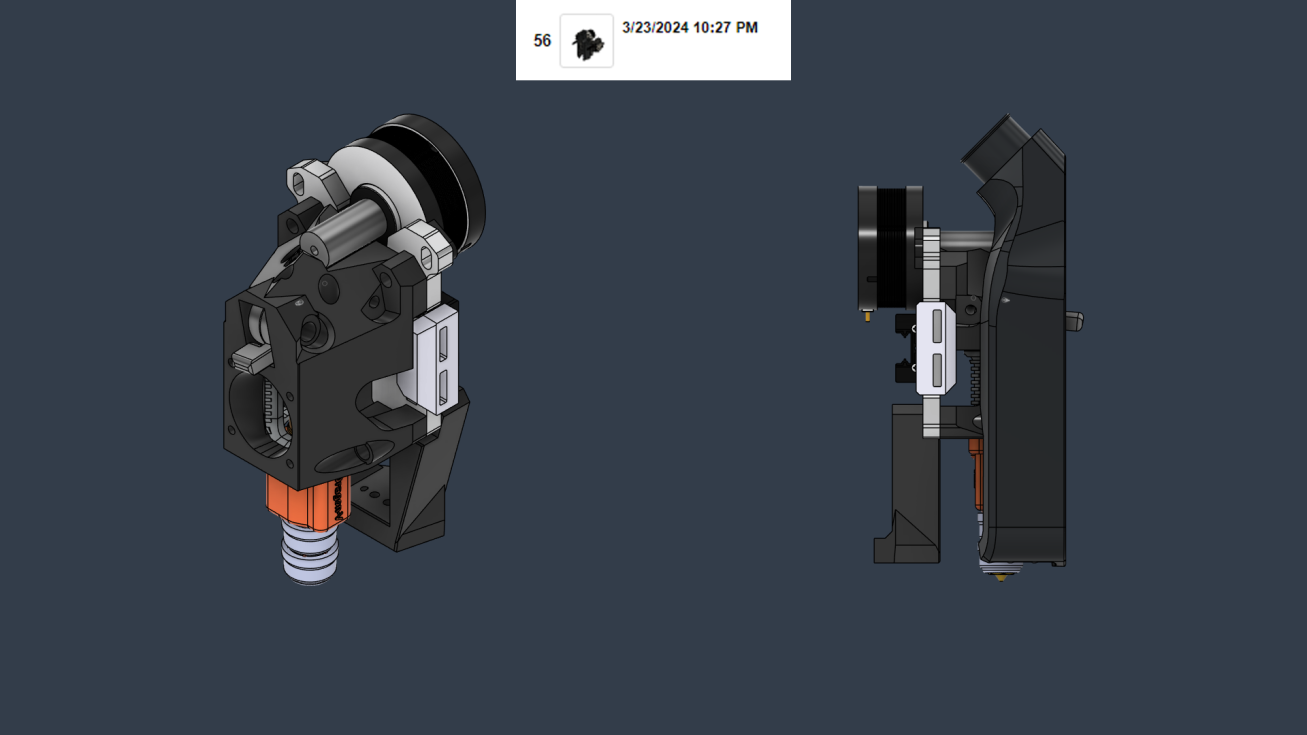

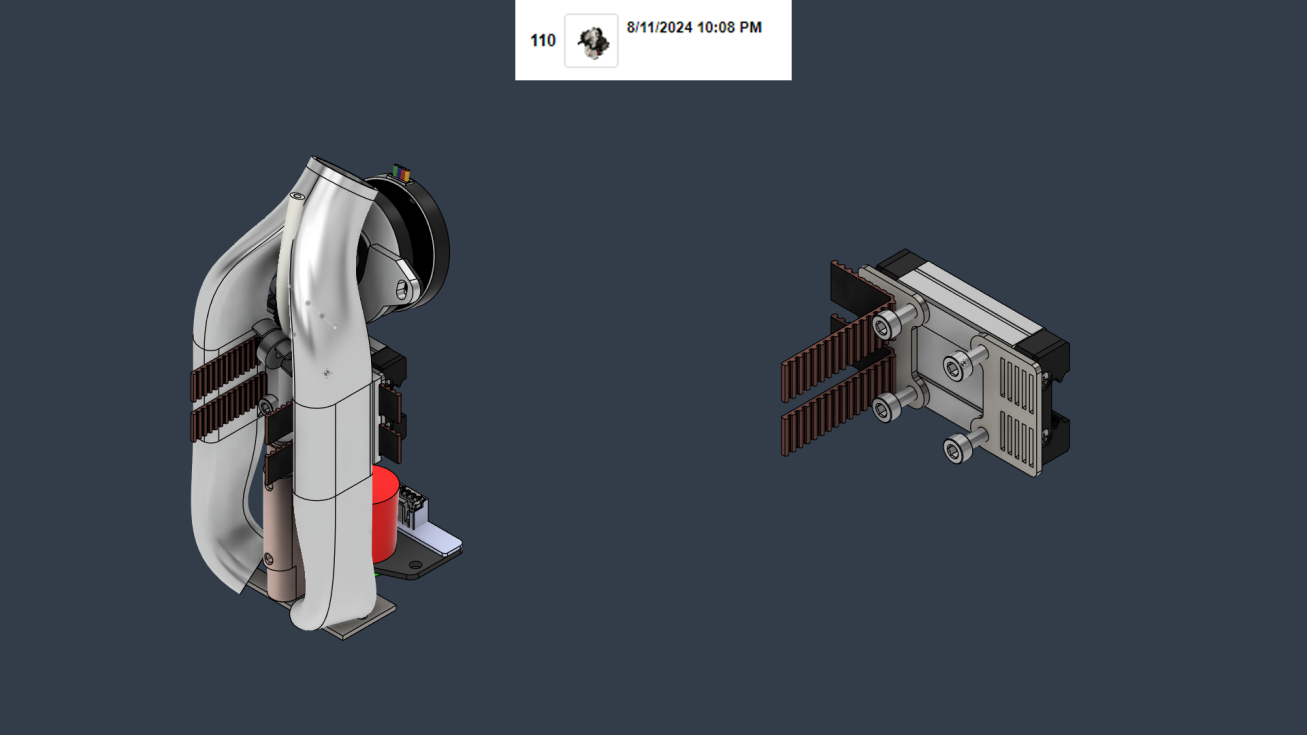

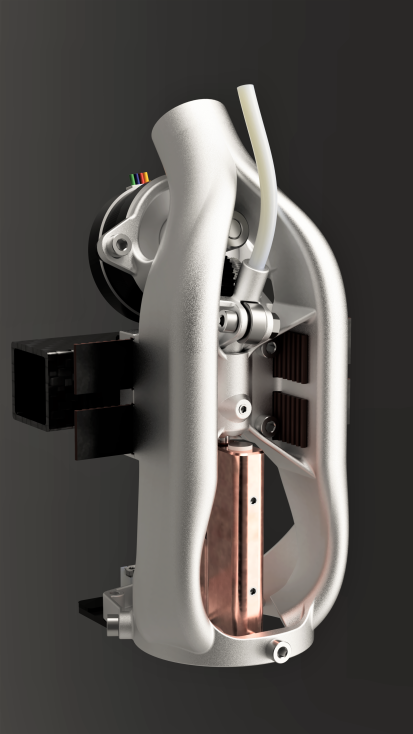

With the growing popularity of affordable SLM I no longer saw any need for modularity. All I wanted to do at this point was to take the material-efficient monolithic idea as far as I could. That was when I started to integrate everything into the ducts and the hotend became double-shear. At this early stage, the layout required a N14 pancake with an extra-long shaft.

With Adeo's first front duct contribution I could visualize things better and the layout was starting to come together pretty quickly.

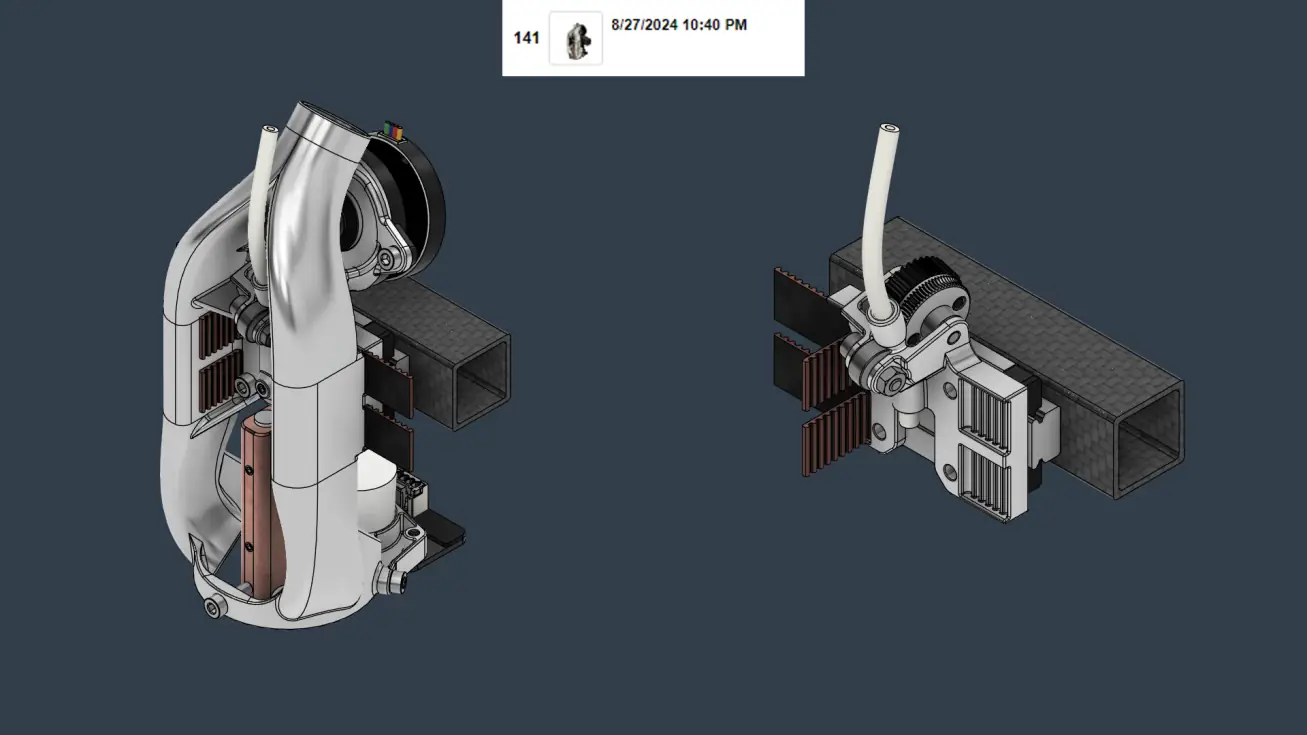

We arrive at the first SLM prototypes we're running now. Other than the super simple Z-joint parts, I had never had any experience with designing for this process. The fact that we could post-process our way out of all issues to end up with completely functional prototypes was a massive win in my book.

We're in the stage with now-co-dev Adeo where we don't only have to find a working solution that fixes post-processing-related issues. Now it's also about, cost, BOM simplicity, maintenance, and other factors we need to consider to send this toolhead design down the same path as the gantry.