Heater Selection - Toolhead Development

While developing a hotend, a critical choice to make is which kind of heater to use. There are a lot of alternatives to choose from, and each one has its pro and cons:

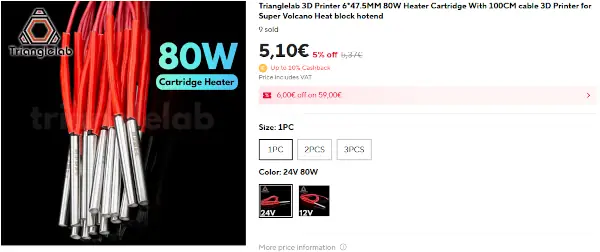

6mm Cartridge:

- The standard, used by most hotends in the past. Very bulky, it dictates where you can place it and how far away it can be from the meltzone.

4mm Cartridge:

- Starting to become available, it should merge the reliability of cartridges with a smaller form factor for more versatile positioning.

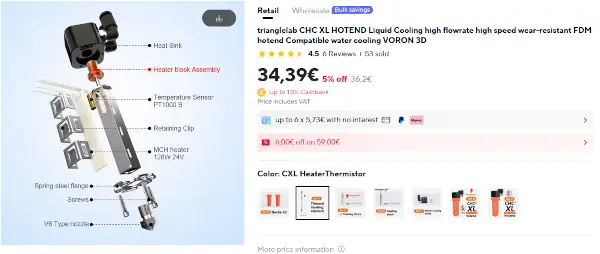

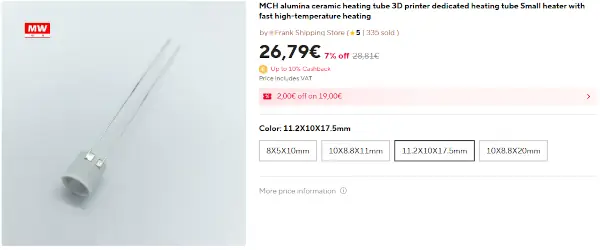

Ceramic Flat Plate:

- Available both PTC (not good for high temps) and MCH (good at high temps too), it's common with newer hotends for its simplicity and the easiest packaging out of all the other options, you just need a flat face.

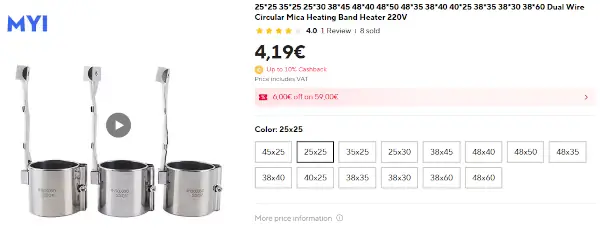

Ceramic Ring:

- It could be used to keep a separate heat zone for the nozzle, reducing the risk of overcooling it. The issue is that controlling the temperature is more difficult since there are no easy places where to put a thermistor.

Ceramic Sleeve:

- Used for injection molds, it could theoretically be put around the whole hotend and has an integrated temperature probe, but it's extremely bulky and compromising with the packaging.

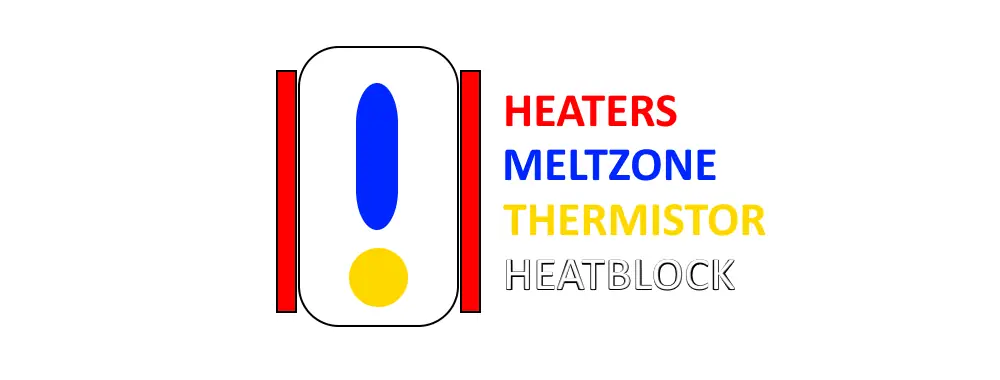

Out of these options the most promising one is the flat MCH plate, as it's trivially easy to integrate, and allows for much slimmer designs with more homogeneus temperature distributions. One possible example is the last picture: two flat plate heaters sandwiching a flat meltzone with the thermistor on the side, leading to nearly perfect temperature homogeneity while keeping the temperature control accurate and reactive.

It's a promising design, and something similar might be tested in the future to better understand its potential.