High Flow Geometry Simulations

I simulated a straight meltzone and two different designs of high flow meltzones, to check the impact of the flow enhancing geometries.

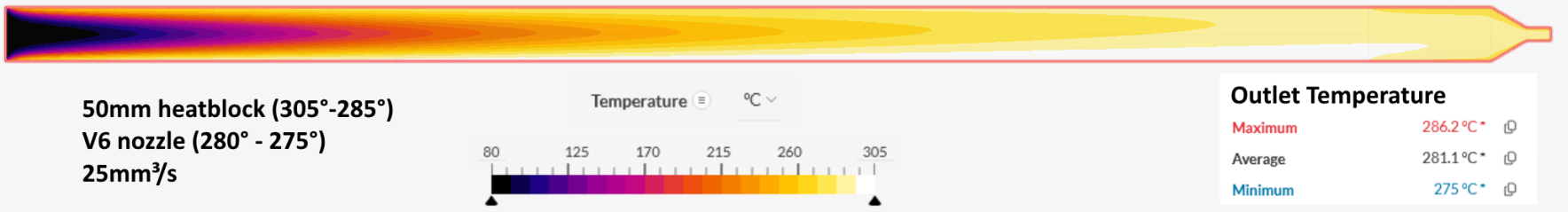

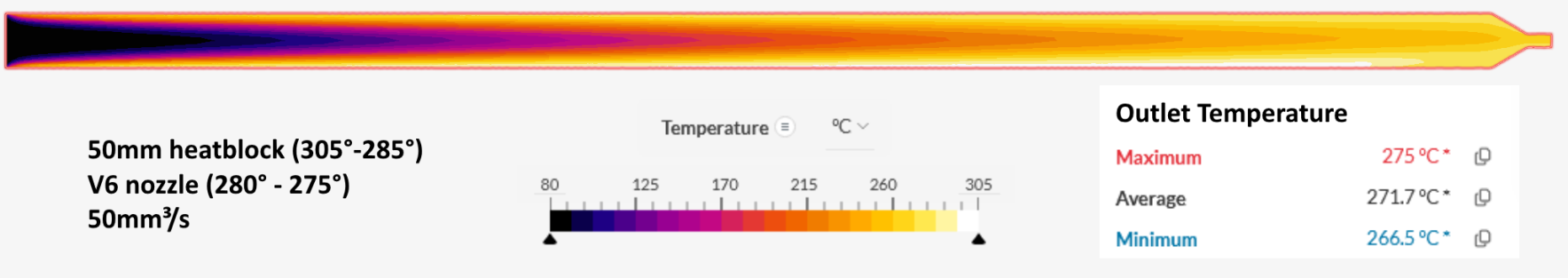

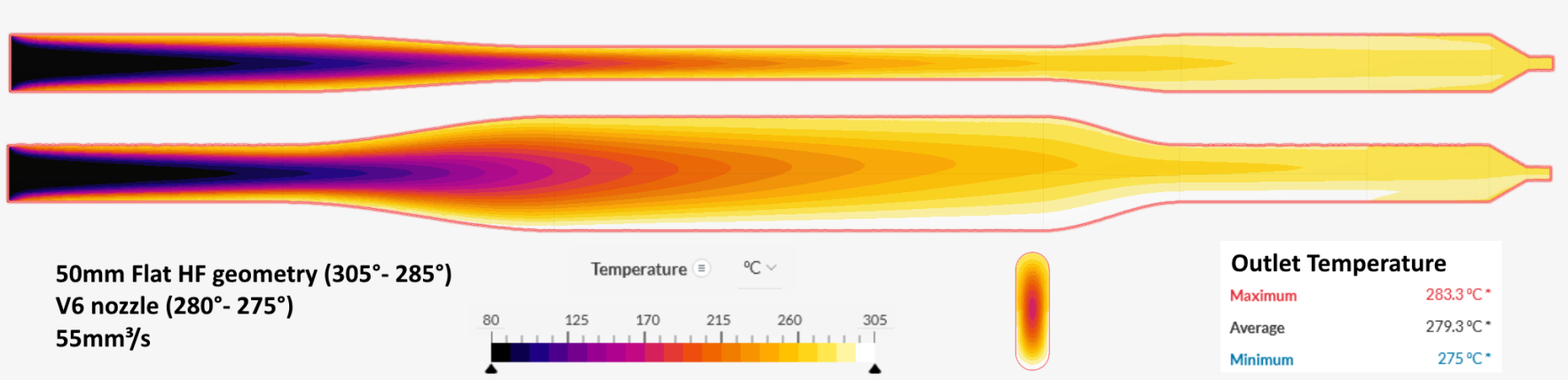

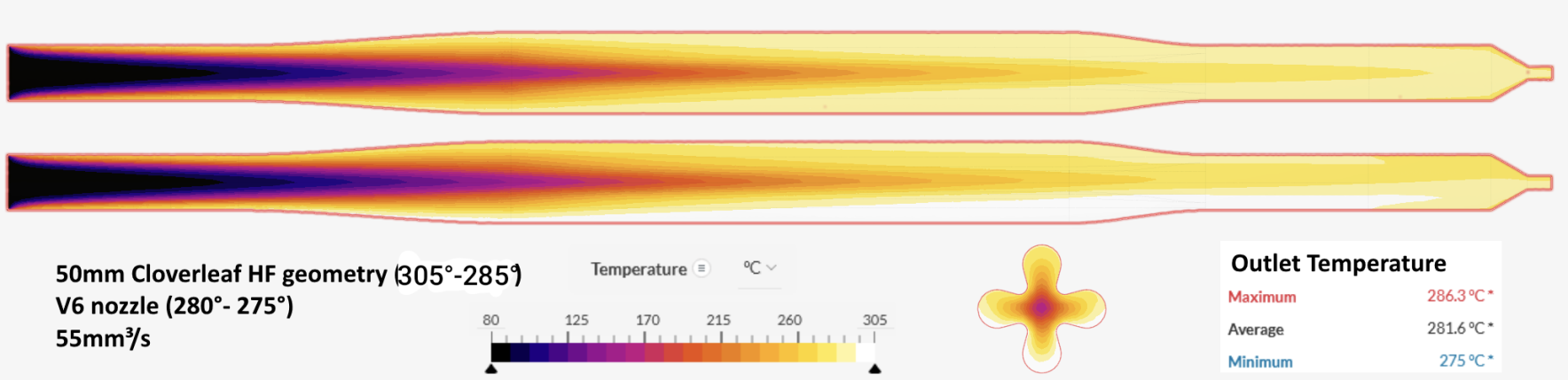

For more accurate conditions I used the results of the previous heatblock and nozzle simulations, so I chose 290° average meltzone temperature, 305° on one side and 285° on the other. The nozzle is colder at 280° for the straight section, and 275° for the outlet. ABS at 80° enters the nozzle at the chosen volumetric speed.

The results are as follows:

-

Straight meltzone at 25mm³/s:

-

Straight meltzone at 50mm³/s:

-

Flat HF meltzone at 55mm³/s:

-

Cloverleaf HF meltzone at 55mm³/s:

The results show that the two HF meltzones make the hotend perform much better at high volumetric speeds, while the straight meltzone struggles.