Hotend Prototyping 1 - Toolhead

The last time Adeo showed us how changing the thermistor location will yield more accurate and less laggy readings.

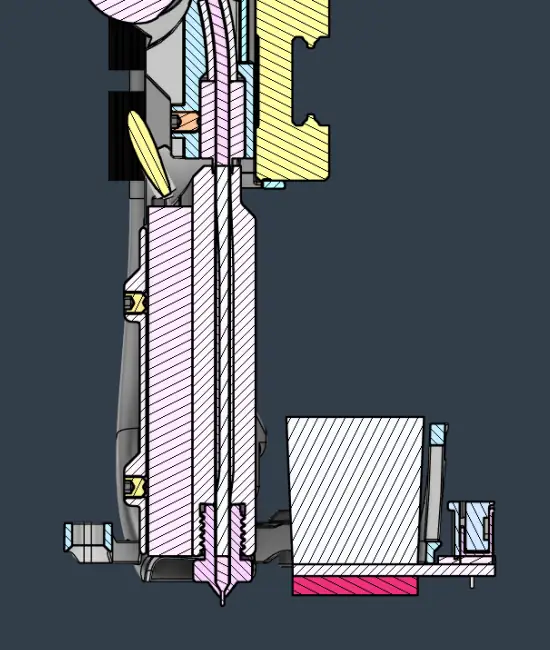

I'm also implementing the more optimized, lower-volume HF geometry we mentioned earlier. The goal is to eliminate that thicker zone in the middle that's colder.

Some testers here had trouble fully inserting the heatbreak and said that the Ti shield still worked fine. So it's safe to say that we have a setup that can enable vertical preload with some changes. Which leads me to try a small contact area, inverted heatbreak design with no M6 thread. The same idea might already be familiar to some of you from Okano's very impressive Tricorn hotend, which you can check out here: github.com/tricornhotend/tricornhotend.com

The SLM block post-processing has probably been the most painful part of the assembly process, and I've been working towards fixing that overhang without introducing other issues. The idea of eliminating the heatbreak thread while increasing the effective melt zone length seems worthy of a prototype.