Idler Losses - Toolhead Development

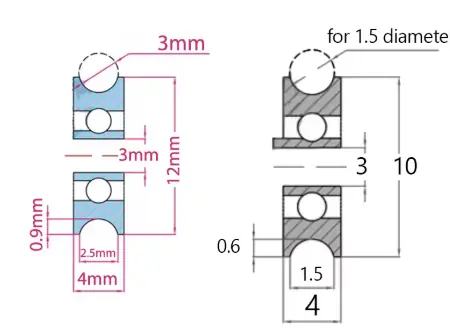

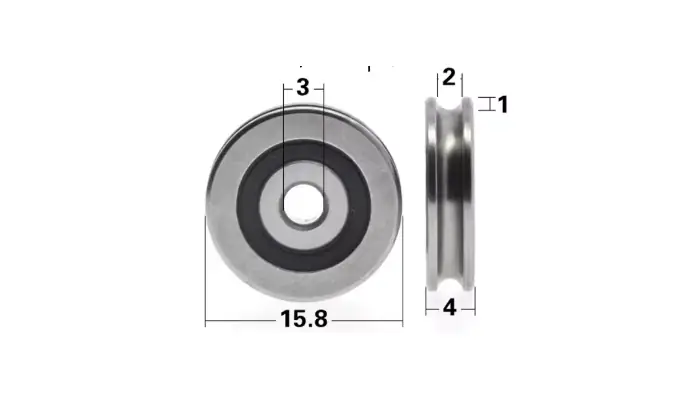

Ever since we talked about this with ProtaDec here, I've been on a hunt for the perfect off-the-shelf U-groove bearing with a 3mm ID so that we can get rid of one SLM part.

I suspect that even without the flat filament drive gear an idler like this will significantly reduce our pushing force losses.

Looking back, it never made any sense to have standard "flat" bearings on single-drive extruders, because having the point contact and more deformation on the side we can't drive is silly. On the other hand, line contact on the side where we wanna cut into the filament as effortlessly as possible with the least amount of radial force also doesn't make sense.

But at least on the driven side, there's an argument to be made about shear stresses in the filament, maximizing the grab and whatnot. This will have to be looked at because I don't wanna move to a completely flat drive teeth without being aware of the downsides.