Monolith Zero Support - Toolhead

.webp)

In earlier posts I claimed that I wanted to reuse the same toolhead for the small printer but with a different belt clamp and no Beacon mount.

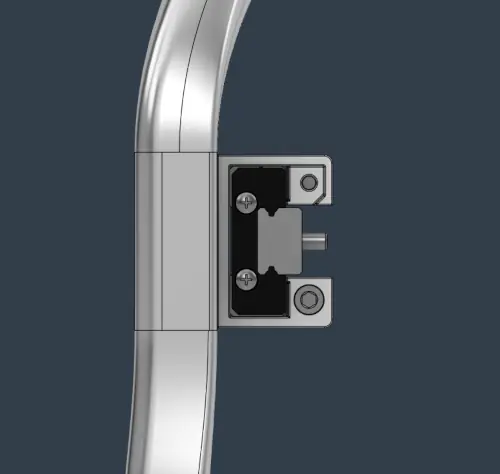

As for the gantry design, I've already decided to keep the sheet metal part count as low as possible, which means putting the belt tensioners on the toolhead. To make the 5-10mm Y overtravel possible with MGN12Hs, clamping the belts to the rear of the carriage seemed to be the ideal solution. The tensioners will be very easy to work with, a proven, Annex K3-style design with 2 long M3 screws.

Since the toolhead COM is close to the center of the rail, I'm hoping that the belt location change won't have a noticeable effect on the X IS results. We'll find out soon enough.

On the other hand, I think the best thing about this belt clamping solution is that every single PFA toolhead narrower than 47-48mm will have full travel and can be easily ported to this gantry without worrying about the belts.

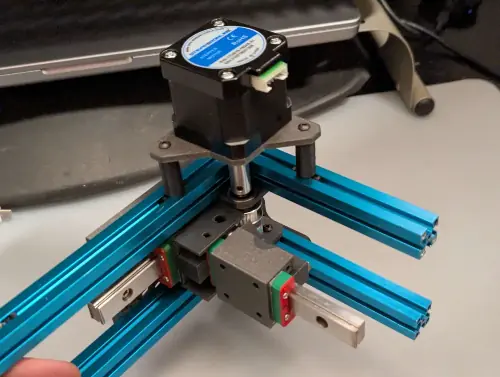

Zruncho is still actively helping me and he used his spare hardware to build this early concept in real life with printed parts. It's been a really motivating environment for development and I appreciate his involvement.