SLM Heater Block Post-Processing, Testing

Aside from the slight delay, I'm pretty impressed by the quality of IN3DTEC's steel parts.

As I've said before I ordered 3 blocks: 1 MZA, 1 no MZA, and 1 no MZA HF. Before post-processing them I was pretty skeptical about using an SLM melt zone, but as it turned out it's easier and cheaper to go MZA-less. The HF geometry is just the icing on the cake.

I bought my blocks with printed M6 threads because I wanted to see how hard it would be not to cross-thread them compared to the printed M3s I tried before. With M6 it's much harder to make this mistake and I see no issues with steel at nozzle spec torque.

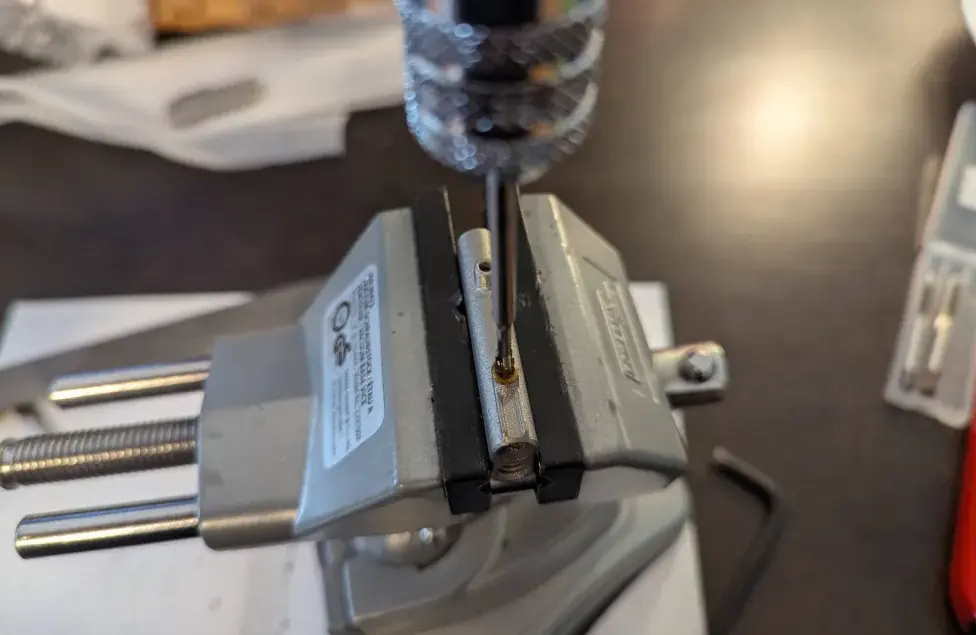

I was planning on using the brass M2 washers from this earlier post, but I got creative and just ran a 4mm drill bit CCW to push out some material around the hole to create a seal. After, I used a cheap hardened steel nozzle and tightened it 10-20 times to get that mirror finish around the hole. At that point, I already knew it wasn't gonna leak. For future versions, this seal will be more pronounced and baked into the geometry.

As for testing, I haven't had much time other than wearing the melt zone in without a nozzle, checking for leaks, and checking the PA by reprinting some older G-code to verify the behavior.

Aside from the very laggy thermistor placement (as DK predicted), the HF heater block can easily keep up with the milled copper + MZA combo. I'm still running the small extruder idler that I can't tighten enough, but it's somewhere between 80 and 90 mm3/s when the backpressure overcomes my current grip levels at 300C.

On top of simplifying the BOM and not having to tap a 50mm long M6 thread, going without MZA will let me move the thermistor much closer to the filament path to reduce the temp lag.

With the heater blocks in a good place, the only thing that's left before the release is improving the shielding that we currently have. I think the evolution of this toolhead design is gonna be more striking with new iterations compared to how the gantry has changed over the last 2 years. So I definitely won't be recommending this for a while to anyone who doesn't wanna be on the bleeding edge, but at some point, we have to start collecting some feedback.