#Monolith Toolhead

Heat Shield and Fiberglass Sleeve

I took other thermal images to add to the collection! I added back the fiberglass silicone sleeve, and measured it with the same conditions as before (255 °C, max speed 9290)…

··Adeo·#Monolith Toolhead

·

Heat Shield and Fiberglass Sleeve

Heatblock Thermal Images 2 - Toolhead

To compare with the previous thermal images, I captured another series of pictures of the heatblock, this time at both the minimum and maximum fan speeds achievable by my 9290. The images were again taken at ~255°C with the chamber at ambient temperature. The first set shows minimum speed, the second is at maximum speed…

··Adeo·#Monolith Toolhead

·

Heatblock Thermal Images 2 - Toolhead

Heatblock Thermal Images - Toolhead

I captured a series of thermal images of the heatblock to better visualize the temperature gradients…

··Adeo·#Monolith Toolhead

·

Heatblock Thermal Images - Toolhead

New Thermal Camera - Toolhead

Thanks to all of you, I acquired a thermal camera to aid with the toolhead development…

··Adeo·#Monolith Toolhead

·

New Thermal Camera - Toolhead

Fan Config Change - Toolhead

The Monolith toolhead uses the ducts as heatsinks, so to prevent heatcreep and increment the efficiency of the coldside it can be useful to have the part cooling fan always running at least at the minimum speed when the heater is on. This greatly helps with heatcreep prone materials, and it lets you print in hotter chambers without any fears…

··Adeo·#Monolith Toolhead

·

Fan Config Change - Toolhead

Klipper Config - Toolhead Development

You guys asked for the Klipper configuration to get started with the toolhead, so here it is. This only includes the critical stuff…

··CloakedWayne·#Monolith Toolhead

·

Klipper Config - Toolhead Development

Hotend Prototyping 1 - Toolhead

The last time Adeo showed us how changing the thermistor location will yield more accurate and less laggy readings…

··CloakedWayne·#Monolith Toolhead

·

Hotend Prototyping 1 - Toolhead

Heater Selection - Toolhead Development

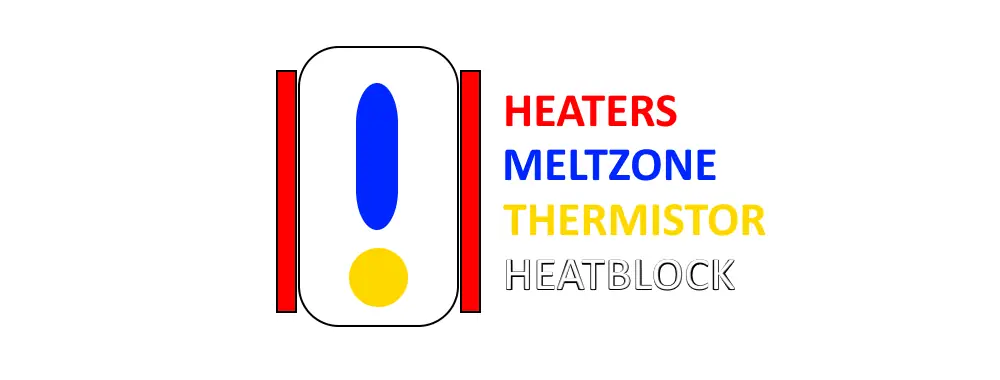

While developing a hotend, a critical choice to make is which kind of heater to use. There are a lot of alternatives to choose from, and each one has its pro and cons:…

··Adeo·#Monolith Toolhead

·

Heater Selection - Toolhead Development

New Heater Block Concept - Toolhead

After testing the current heatblock design, one thing that stands out is that the temperature isn't consistent in the cross section and the thermistor lags behind a while. This isn't ideal and can cause degradation in the filament, and print quality issues in general…

··Adeo·#Monolith Toolhead

·

New Heater Block Concept - Toolhead

PLA Torture Test - Toolhead Development

I wanted to get back into PLA printing to learn more about the toolhead's thermal performance. I chose this skull pencil holder because it has a crazy amount of retractions…

··CloakedWayne·#Monolith Toolhead

·

PLA Torture Test - Toolhead Development