The Layout - Monolith Zero Development

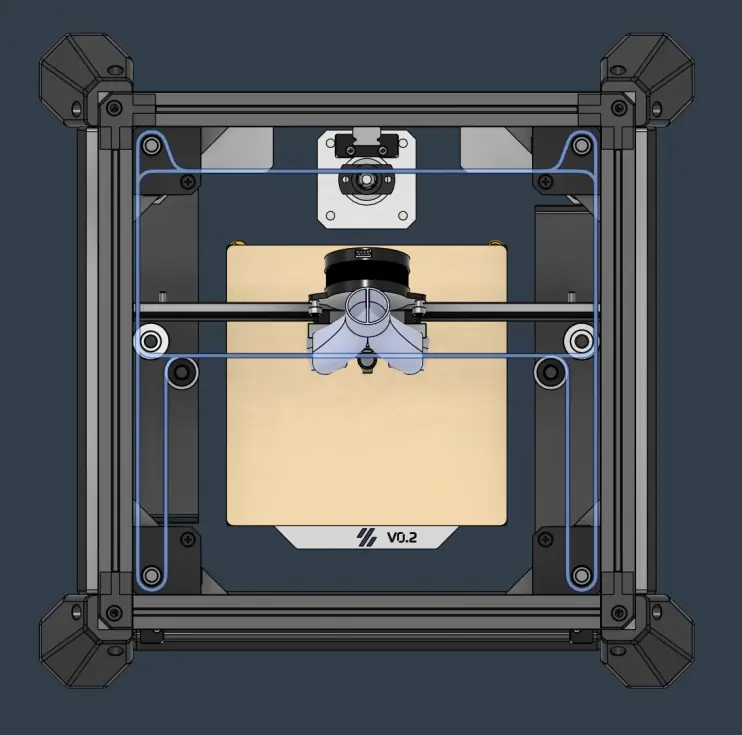

Belt path: As it turns out the structural tophat with the steppers in the same location is compatible with a more space-efficient, live-shaft-ready, front rail Monolith belt path.

X-axis: The X is likely gonna be an unsupported MGN12 rail with a 12H carriage. The SLM XY joints directly mounted to the rail would reduce this unsupported rail length to barely over 120mm. This would provide adequate torsional rigidity for a balanced toolhead and at a very low part count.

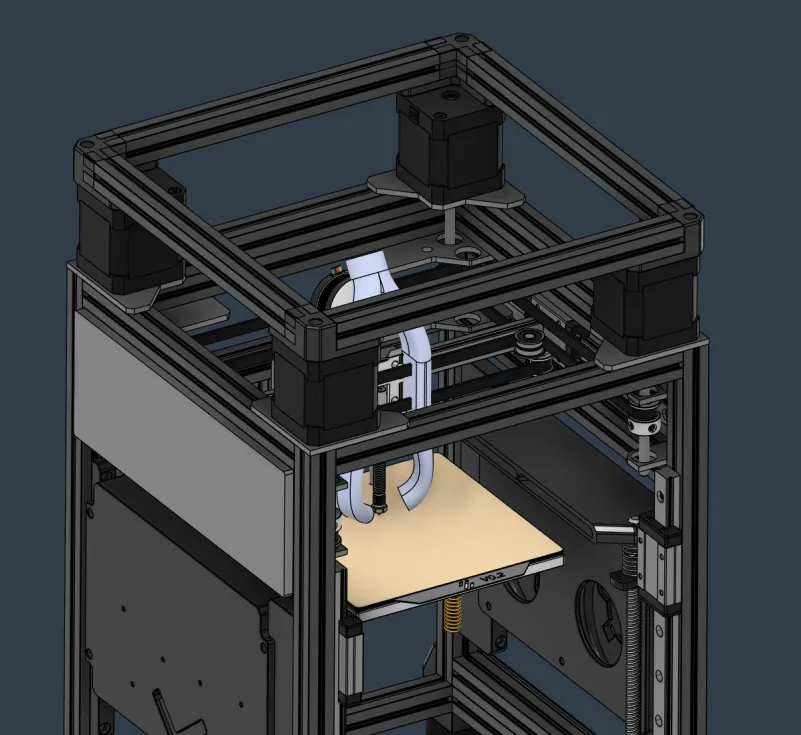

Y-axis: The MGN12 rails would be mounted to thick steel plates bolted to the frame. The structural side panels would have a cutout there to keep everything compact.

Z-axis: Triple lead screw rigid design that reuses the original stepper from the V0 driving the front lead screws with a closed loop belt. MGN12H or reused MGN7H option.

Toolhead: To have the full 120mm X-travel with a 12H carriage, this very similar SLM CPAP toolhead would have the belt clamps in front of the ducts and the heatbreak. This means that the toolhead can slide behind the XY-joint smooth idlers in the front without an issue. The COM will be optimized for this layout.

Theoretical performance: With 800mm long 6mm GT2 belts, coupled with 5-600g of moving mass this thing already has higher theoretical IS than a 12mm AWD 300mm Monolith. So I won't be chasing anything more than that with wider belts, because I'd like to see a nice belt limited IS that's easy to compensate for.

So overall, the goal is to make something with fewer large parts rather than with more small parts. No M2 hardware anywhere and I'll minimize the interaction with the 1515 frame.