Volumetric Flow Rate Test 1 - Toolhead

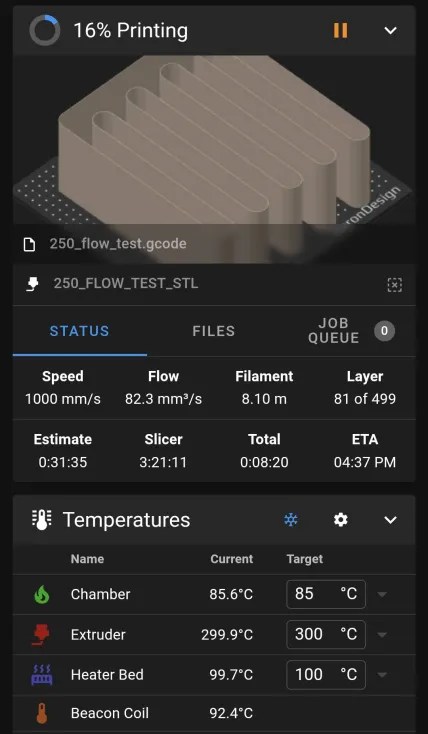

Test conditions:

- Experimental toolhead with HF hotend geometry

- 80W heater, PT1000 thermistor

- 17mm LDO extruder, @0.5A and 36V

- 40% 7040 CPAP

- LDO black ABS @300°C in an 85°C chamber

- 0.2mm LH, 0.5mm LW

Today, I decided to load up some good old black ABS to see what flow rate I can achieve with the current setup. The immediate issue I encountered was the inadequate extruder torque after a simultaneous fan speed and volumetric flow rate increase. The drop in temperatures right after the start of the second layer increased the backpressure just enough that the otherwise sustainable, steady-state flow rates didn't pass without skips in the first few layers.

My solution to this was to increase the modest extruder current from 0.35A to 0.5A. This increased the maximum sustained flow rate from 60mm3/s to 83mm3/s. The latter seemed to come close the current hotend's melting capability, because very subtle ripples formed on the vertical surfaces, indicating the plastic wasn't properly melted.

The 17mm LDO was just enough for this hotend at 0.5A, but it fell short in some instances at only 0.35A. On the other hand, the 40% CPAP and the 300C hotend melting 83mm3/s of plastic are pretty much maxing out my 80W heater with an average of about 90% PWM.

Both of these things point towards what we already knew: the next stage of the toolhead development should heavily focus on the thermal efficiency, leveraging integration to lower the wattage at the same volumetric flow rate.

For part 2, I'll probably run the same G-code using the 20mm LDO stepper. Maybe there is a bigger difference than I expect.