SLM XY Joints Installation - Gantry

Removing my abused sheet metal XY joints was a walk in the park. I'm still happy about how well these held up to the countless rebuilds and even the 12mm conversion.

Since my Beta LDO kit is almost here, I didn't feel like rebuilding the 12mm sheet metal gantry for 10mm EPDM only to make a couple of clearance and IS checks.

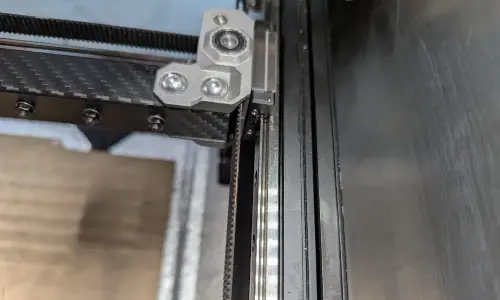

The Y rail replacement was a nightmare without the panel removal; that 1 hour or so felt a lot longer. The good thing about the MGN12H bolt pattern and this layout is that all 4 of the screws are still accessible after the rest of the joint is already put together. One of them is a little tricky, but with the tweezers I have for soldering, I managed to get it done.

I will have a more detailed comparison between the MGN9H XY joints in the milled kits, and these SLM MGN12H ones.

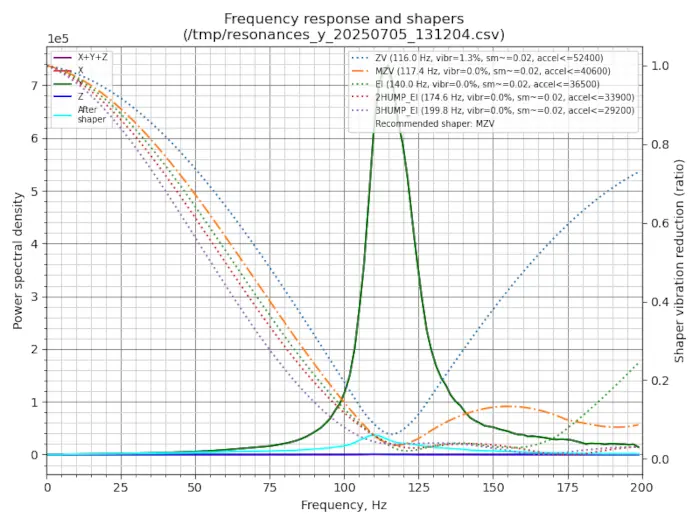

As for the initial input shaper results, I can confirm that the weight math seems about right. Almost identical frequency to my previous 9/10mm results with the sheet metal MGN9H XY joints.

UPDATE: The updated IS graph is from a properly built 10mm gantry with these XY joints and not the mixed 12/10mm setup. We're currently working on a better version. Based on member feedback, the crush ribs can be pretty inconsistent, and it would be better to have these as a single part. Unfortunately, that would mean no integrated live shaft support. Milling these would also be pretty hard because the countersinks aren't accessible.